So it is time to test out the alternator. This is the moment of truth because it determines how well I have done on all the other steps up until this point. In fact the wind turbine is really mostly done. Sure there is a lot to do to get the electrical system working and erect it on a tower, but the turbine itself is pretty much done.

The Homebrew Wind book has a number of suggestions for testing it out. You can do a couple of quick and dirty tests like shorting out the leads and making sure the alternator is reacts correctly. The alternator should get “lumpy” to turn when two leads are shorted. It should be smooth but difficult to turn when all three AC leads are shorted. This guy passed those test for sure, so I don’t think there are any obvious problems with the coils.

I bought a full bridge rectifier the other day off of ebay that should work for converting the alternating current coming out of the turbine into direct current. It only cost $10 so I thought I’d try it out. It is rated for 55 amps but I’m not sure what kind of voltage it can handle. I bet it will work since it was built specifically for this type and size of wind turbine. This turbine should only produce about 35 amps at peak output, so I think it will work. Here it is below…

So it appeared to work fine once it was hooked up.

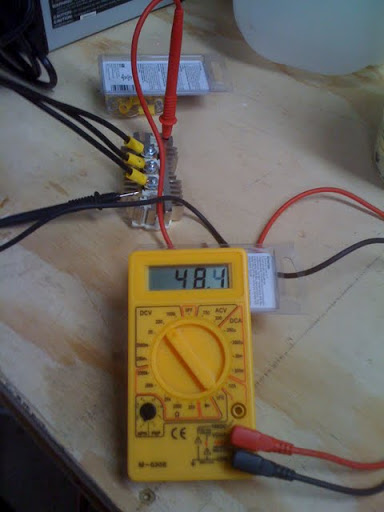

The DC leads are a bit strange on this rectifier. There aren’t any screws so I will need to tap the holes on it at some point. Anyway, at this point I wanted to do a little more testing like the Homebrew Wind Power book calls for. It says this turbine is supposed to have a cutin speed (lowest speed at which it produces the rated voltage of 48 volts) of about 140 RPMs. They say it can be within 20 or so RPMs in either direction. I don’t have a laser tachometer yet so I estimated the RPMs at 48 volts a couple of times and it looks like this alternator is producing 48 volts at roughly 135 RPMs !!! I will check it again when my tachometer arrives, but I think we are good.

I haven’t testing amperage at all but it seems to be creating quite abit of power. I hooking a 12 volt motor to the DC leads and just by hand cranking the alternator the motor starts to scream!! I can’t wait to do a power curve of this thing. I really want to see a curve of wind speed, RPMs, voltage, and amperage. I’ll need to figure out a good way to get all this information without having a wind tunnel to test it.

I ordered some fiberglass (WindMax 9.2 foot) blades the other day because I am not sure whether I am going to carve the specified wood blades for this turbine or not. I need to think a bit more about how these smaller blades are going to affect the performance. I bought slightly smaller blades because I think it is better to have a over powering alternator as apposed to a overpowering set of blades. the air gap between the magnet rotors can always be widened to produce a bit less inductance if I need to match the alternator to the blades. This is a bit of a waste of magnets and copper but it is tough I guess to match things perfectly, so whatever…